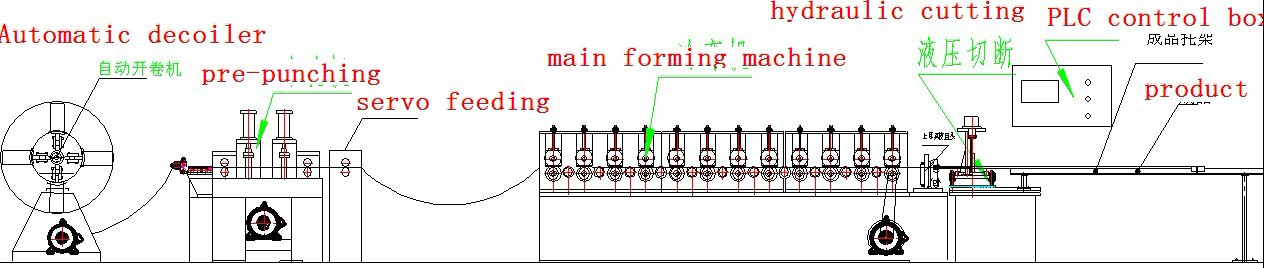

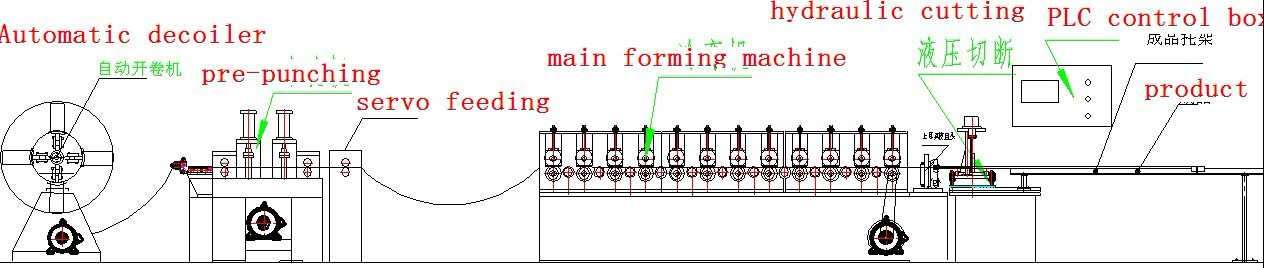

1. Profile:

1.1 Thickness: 0.5-1.2mm

1.2 Specification:door frame

2. Process

De coiling—pre-punching---roll forming-- hydraulic cutting---product

3. 3T automatic inner tighten de-coiler

3.1 coil inner diameter φ450mm-φ530mm

3.2 coil outer diameter φ1300mm

3.3 material width available 20mm-300mm

3.4 max carrying capacity 3000kg

3.5 Auto-de coiling motor: 1.0kw

4. Levelling machine

4.1 7 shafts levelling machine

4.2 shaft diameter 50mm

4.3 motor 2kw

5. Hydraulic punching

5.1 Mold material: Cr12

5.2 Power : 5.5kw

5.4 two cylinders ( one for lock holes, one for hing holes )

5.5 four pairs punching moulds ( for left and right side open )

6. Roll Forming Machine

6.1 Shaft diameter 50mm

6.2 Roller Material: Cr12

6.3 Stations: 14 stations

6.4 Transmission: gear wheel

6.5Forming speed: 10-15m/min

6.6Motor: 5.5kw

6.7 Structure: independent stand

6.8 Voltage, Frequency,Phase: 380V, 50Hz, 3Phase

7. Hydraulic cutting

7.1 Material of blade or mold: Cr12 steel

7.2 Power :5.5 kw

7.3 fly cut

8.Control system

8.1 screen: touch screen

8.2 PLC: control length and quantity

8.3 Manual and automatic